DISC FILTER

Key words:

Classification:

FILTERING MACHNE SERIES

- Detail

-

- Commodity name: DISC FILTER

- Commodity ID: 1197896610017333248

Overview

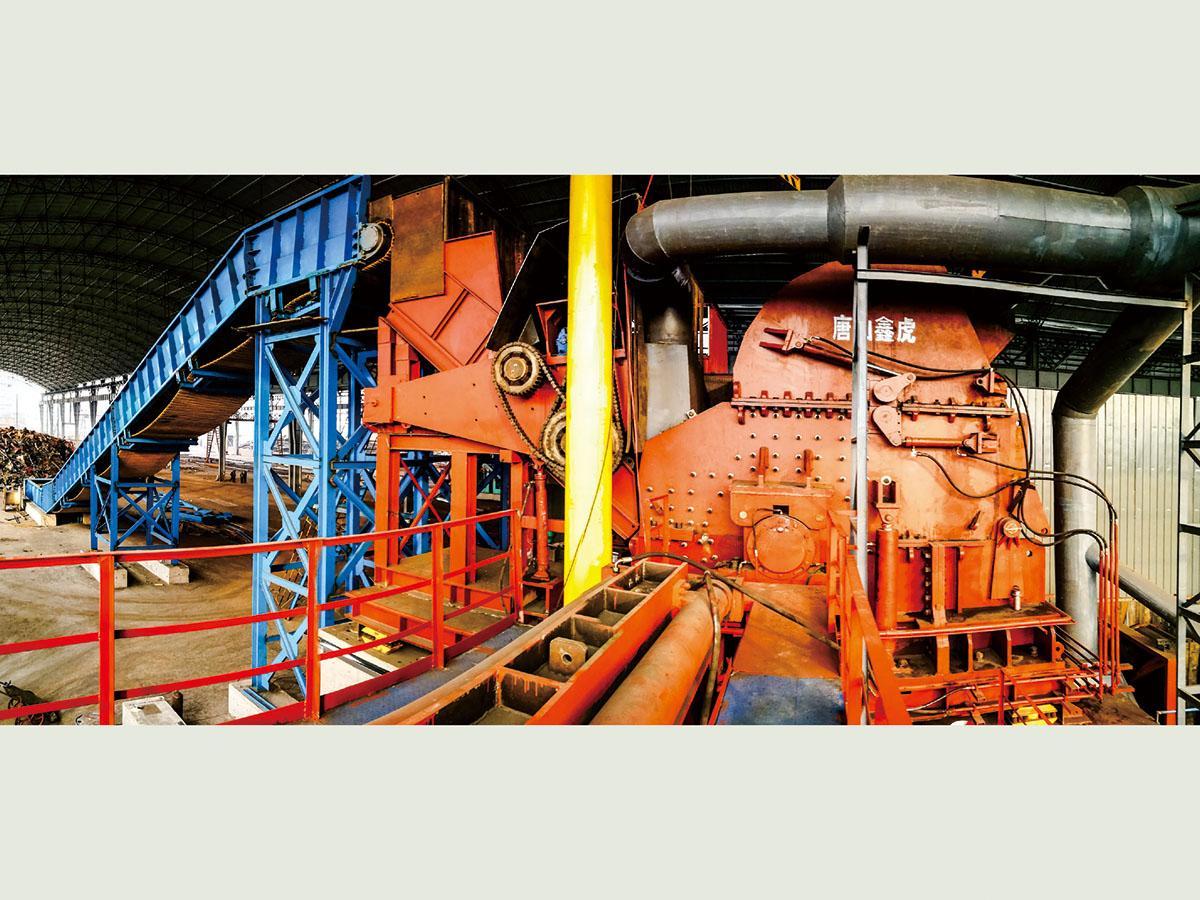

The ZPG disc vacuum filter is a device that utilizes the vacuum as filtering power to separate the solid from the liquid in the pulp. It is an excellent filtering equipment designed for filtration of iron concentrate and non-ferrous metal concentrate. The ZPG series heavy-duty disc vacuum filter used for metal ores has fully made use of the advantages of similar foreign products. In view of the high density, quick settlement and strong impact force of filtrate containing solid particles on the filtering pipe, the optimization design of overall perform-ance and reliability among components has been conducted, featuring solid structure, stable oper-ation of filter disc, automatic variable-speed powerful stirring, reliable seal of shaft end, high durability of wear-resistant ceramic filtering pipe, high strength and high porosity of filtering fan, and smooth surface, high cake discharge rate and long service life of the high-strength filtering cloth, thus to ensure the excellent dewatering indicators of the metal minerals in solid-liquid separation.

Working principle

The disc type vacuum filter is a kind of solid-liquid separation equipment, and the filter disc is driven by the motor through reducer and open gear transmission, to enable the filter to rotate a certain speed in the trough filled with pulp. By means of the pressure difference generated on both sides of the filter medium by the vacuum pump in the adsorption zone, the solid materials are absorbed onto the filtering medium (filtering cloth) to form the filter cake. When this part of the filter disc is separated from the pulp and enters into the dewatering zone, the moisture is continuously separated from the filter cake under the suction force of the vacuum, and then discharged through the filtrate pipe and distribution head; in this way, the filter cake is dried. After passing through the unloading area, the filter cake is unloaded by the reverse-blowing self-filtering disc, and then falls into the discharging trough; thereafter, it is transported away by the collection conveyer.The whole process will be continued without interruption.

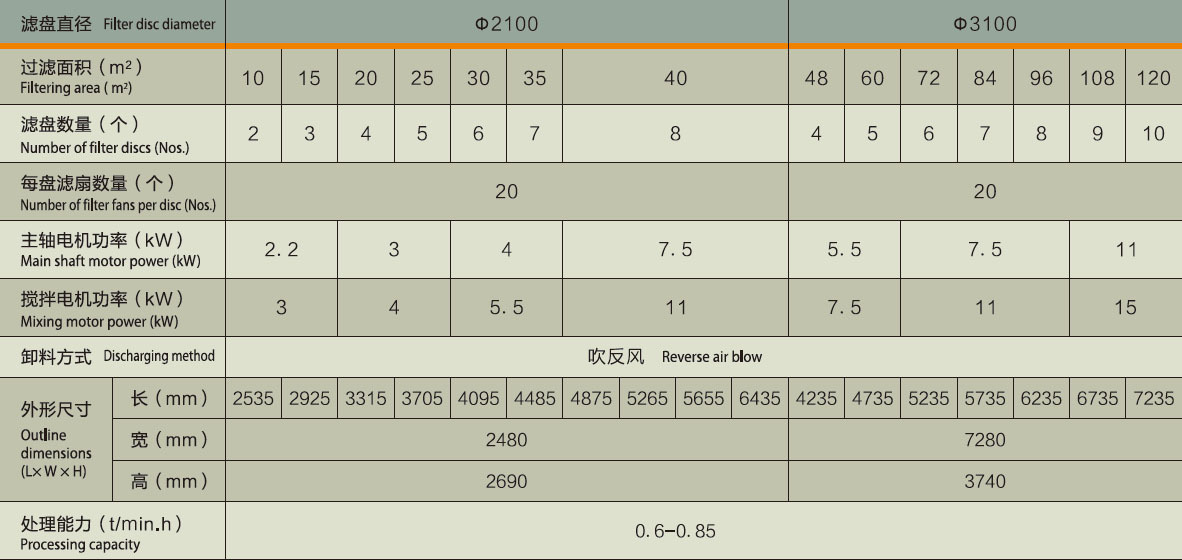

Note: depending on the hardness and thickness of the materials, the processing capacity (refer to the quantity of raw ores processed) listed below is for reference only.

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!