The company was founded in

Annual production capacity

Company covers an area

Professional R & D Team

Welcome to know our products

Get more product service information of Xin Hu mining machine

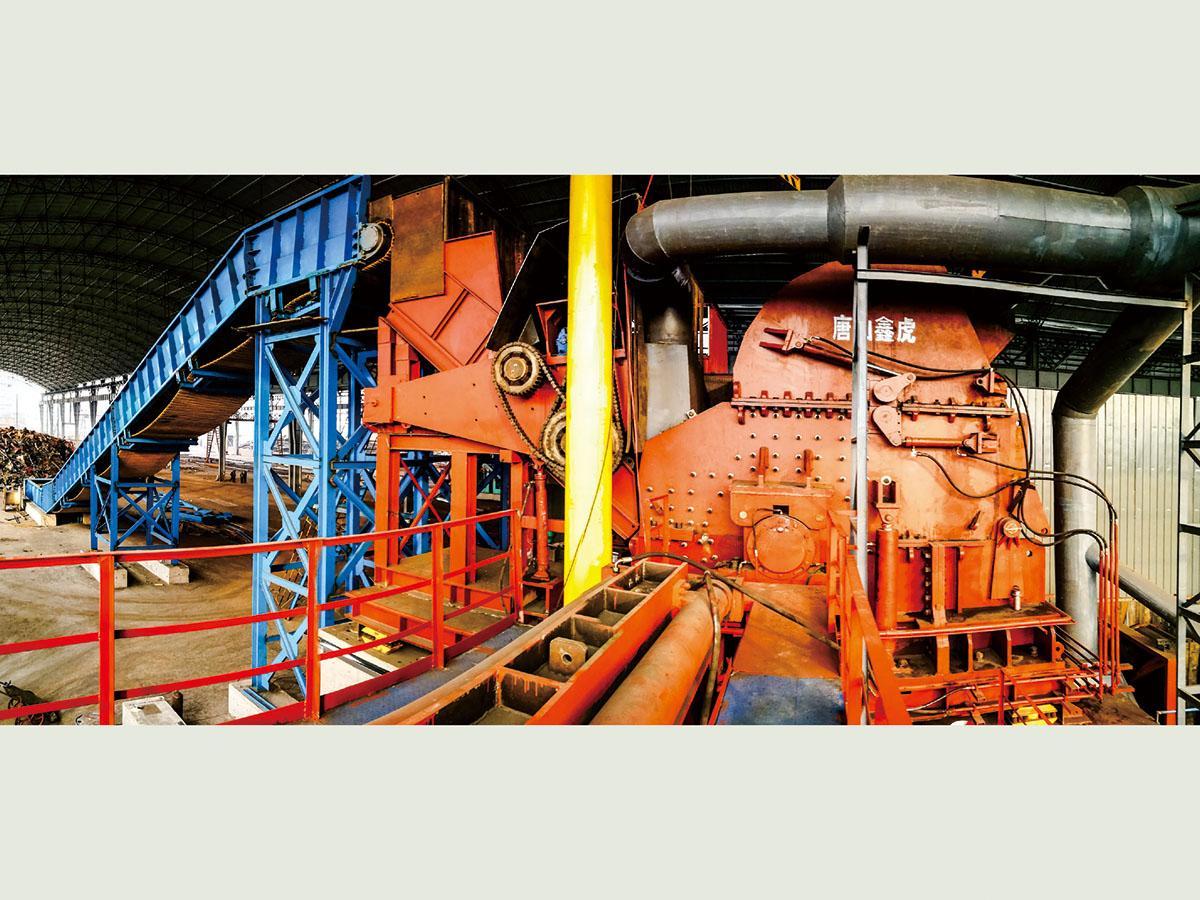

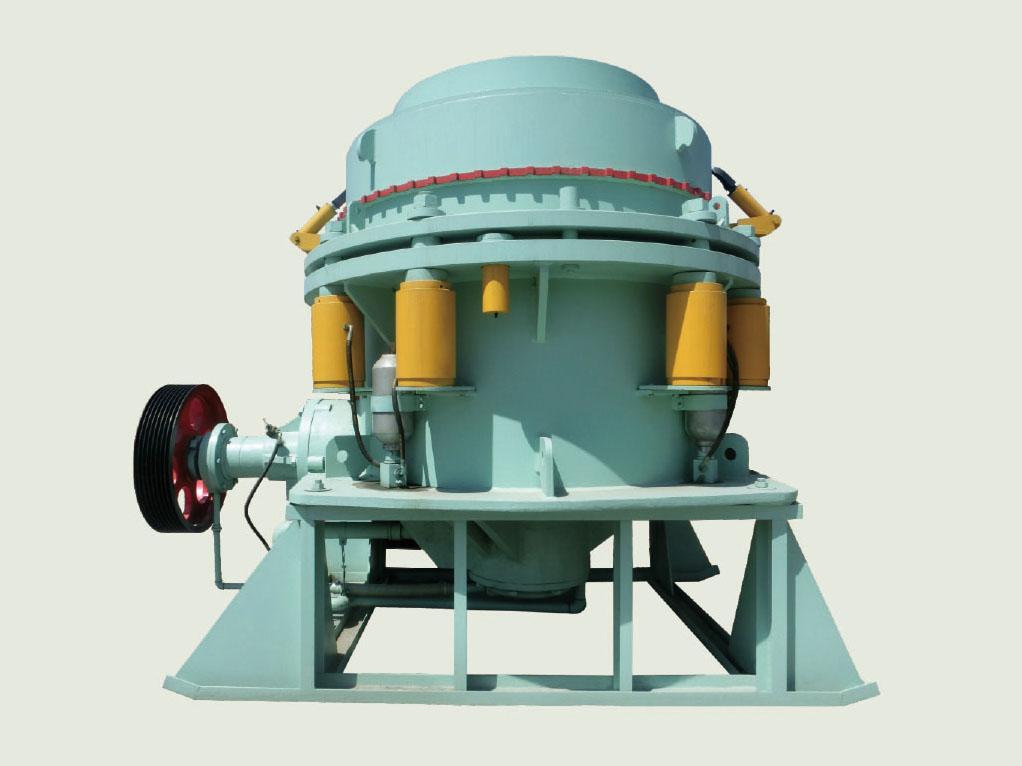

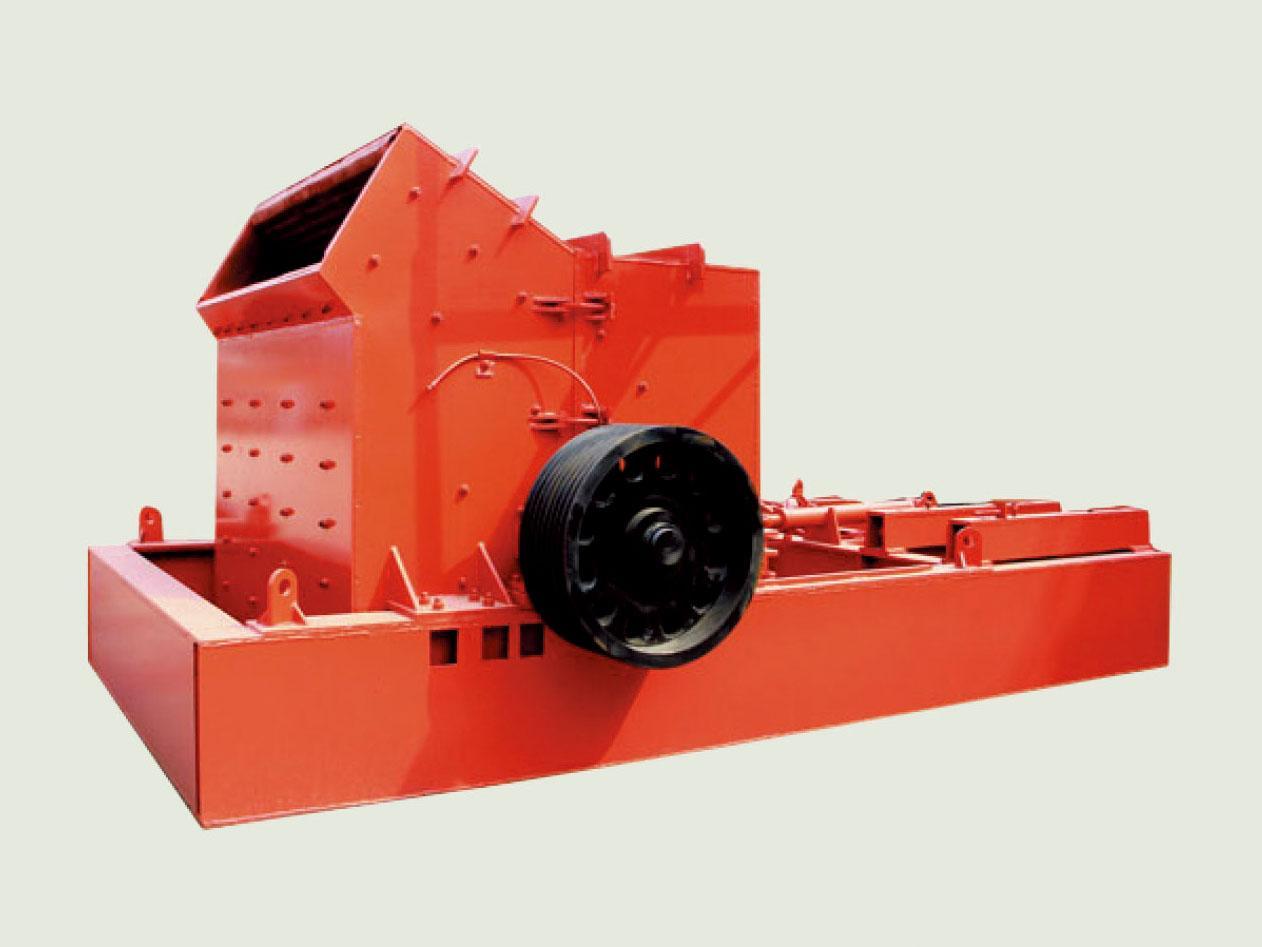

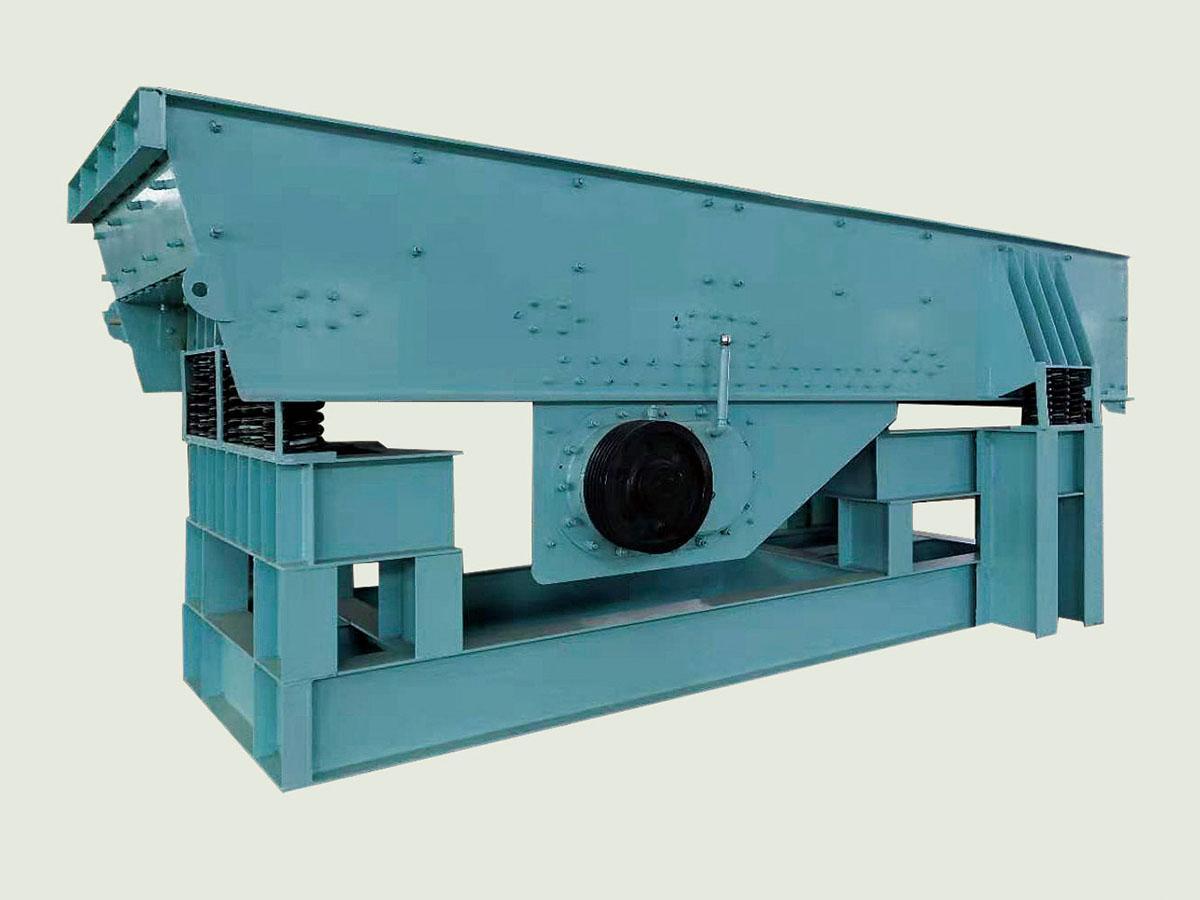

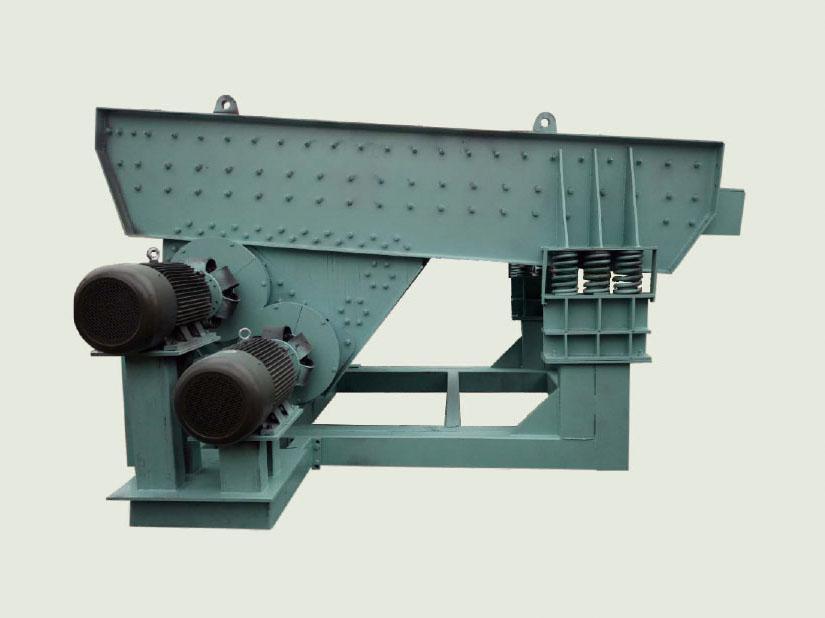

Tangshan Xinhu Heavy Mining Machinery Co., Ltd. was founded in 1998. It is located in the core areas of the two economic circles around Beijing and Tianjin and the Bohai Rim, and the mining machinery production base in North China-Zunhua Equipment Manufacturing Industrial Park. The company covers an area of 180 mu, with a construction area of more than 100,000 square meters and an annual production capacity of 100000 tons. It is a modern processing enterprise integrating R & D, manufacturing and installation, supplying complete sets of equipment for mining, metallurgy, building materials, chemical industry, environmental protection and other industries.

Xinhu StrengthNews

2017/09/07

On September 4th, more than 100 city leaders and attendees, including Li Guifu, Secretary of the Zunhua Municipal Party Committee, and Dong Xuezhong, Mayor, used a day to conduct on-site observations of 30 key projects recommended and reported for the first half of 2017 in 27 townships (streets) and 6 economic authorities in the city.

See more →On September 4th, more than 100 city leaders and attendees, including Li Guifu, Secretary of the Zunhua Municipal Party Committee, and Dong Xuezhong, Mayor, used a day to conduct on-site observations of 30 key projects recommended and reported for the first half of 2017 in 27 townships (streets) and 6 economic authorities in the city.

Xin at the beginning of the year of the tiger Over the past year through the steps, leaving is hard and hardships and mount on the outlook for the New Year, you I still need to take a higher ideal and goal to continue to pay. Thank you for the past year the new and old customers, people from all walks of life to my company's support and care and at the same time also thank you for "xinhu" prosperity, prosperous shed sweat all employees.

The main ways to improve the efficiency of ball mill output 1, the grinding system automatic control. According to the noise of ball mill, electric ear method is used to control the electromagnetic vibrating feeder or belt feeder, automatic regulation and control grinding material within appropriate materials uniform to join, make the material inside the mill keep the best state, which can improve the mill production. 2, strengthen to ball mill (ball mill) ventilation in grinding. Has a certain wind speed grinding, the grinding process of powder can be taken away by the airflow in time, reduced the buffer action of micro powder, can improve the efficiency of grinding, the quality of the products will not be affected. Grinding in ventilation speed due to grinding different materials and different, generally 0.3 1.0 m/s. When the well ventilated, ground water vapor discharge in time, within every storehouse board grate hole is not blocked, grinding medium adhesion phenomenon is reduced, and can reduce the temperature in grinding, this is advantageous to the mill operation and improve the quality of products. Production of high strength grade of cement should choose low speed; Conversely should choose a bit bigger. 3, into the ball mill (ball mill) ground water inside. Should produce a lot of heat when grinding cement, the quality of cement and the grinding efficiency are bad, and affect production. Water with high pressure air atomizing spray into the grinding, grinding away effectively within the quantity of heat, cooling in the mill. Water is a surface active substance, easy to make particles get nexus of contracts for collapse, prevent package material on the grinding medium. Within the water spray is determined according to the grinding temperature and grinding, generally not spray under 1000 c. In addition, water quantity according to the grinding clinker temperature, accounts for about 1% - 1% of cement quantity, and the spray into the ground moisture to evaporate completely, no residual moisture. Water from the grinding head or tail water spray can. When the grinding material at high temperature, water from the grinding head is advantageous, whereas in the general case is grinding of tail water spray. In the grinding water can make the production capacity increased by 5% - 10%. To ball mill (ball mill) mill grinding agent, can improve the production capacity of around 10%, general with triethanolamine, mix accounted for 0.04% of the grinding material - 0.1%.

"There is excess steel production capacity has reached a very serious, dissolve the excess production capacity will be issued a number of measures, and give play to the role of market main body decisive." On November 21, China steel industry association executive vice President of Mr Zhu in the international iron and steel association's "green manufacturing - the future of steel and car" international symposium on the "daily economic news" reporter said.

Scrap steel is a raw material that can replace iron ore in steel production. To some extent, the development and application of scrap steel resources is an important way for the steel industry to achieve energy conservation, emission reduction, clean production, circular economy, and alleviate the crisis of iron ore resources. The recycling rate of scrap steel in China in 2012 was 19.9%, far below the world average of 48.3%. The trend of the development of China's scrap steel processing industry is to use scrap steel crushers for sorting and processing, and utilize high-tech such as environmental protection and mechatronics integration to develop new comprehensive scrap steel treatment technologies, which can form an environmental protection industry and new economic growth points.

According to relevant data, China's scrap steel is currently entering a period of rapid growth and may reach 300 million tons in the next decade. Scrap steel is one of the main iron raw materials for steelmaking, which not only carries energy and saves energy, but also is environmentally friendly. However, for a long time, the recycling of scrap steel has not been ideal.

The technology level of mining machinery and equipment capacity, is a measure of a country's industrial strength important symbol. This paper briefly introduces the classification of the mining machinery and role in national economic construction, and put forward the economic construction oriented market driven, computer technology and information technology, and other multi-disciplinary integrated support as well as the harmonious development between human and nature is the driving force for the development of the mining machinery manufacturing.

To adjust industrial structure, focus our dissolve excess capacity and innovation development, is put forward by the central economic work conference concluded by one of the six large task in economic work next year.

Explore more

SPEECH

HONOR

culture

Factory Display